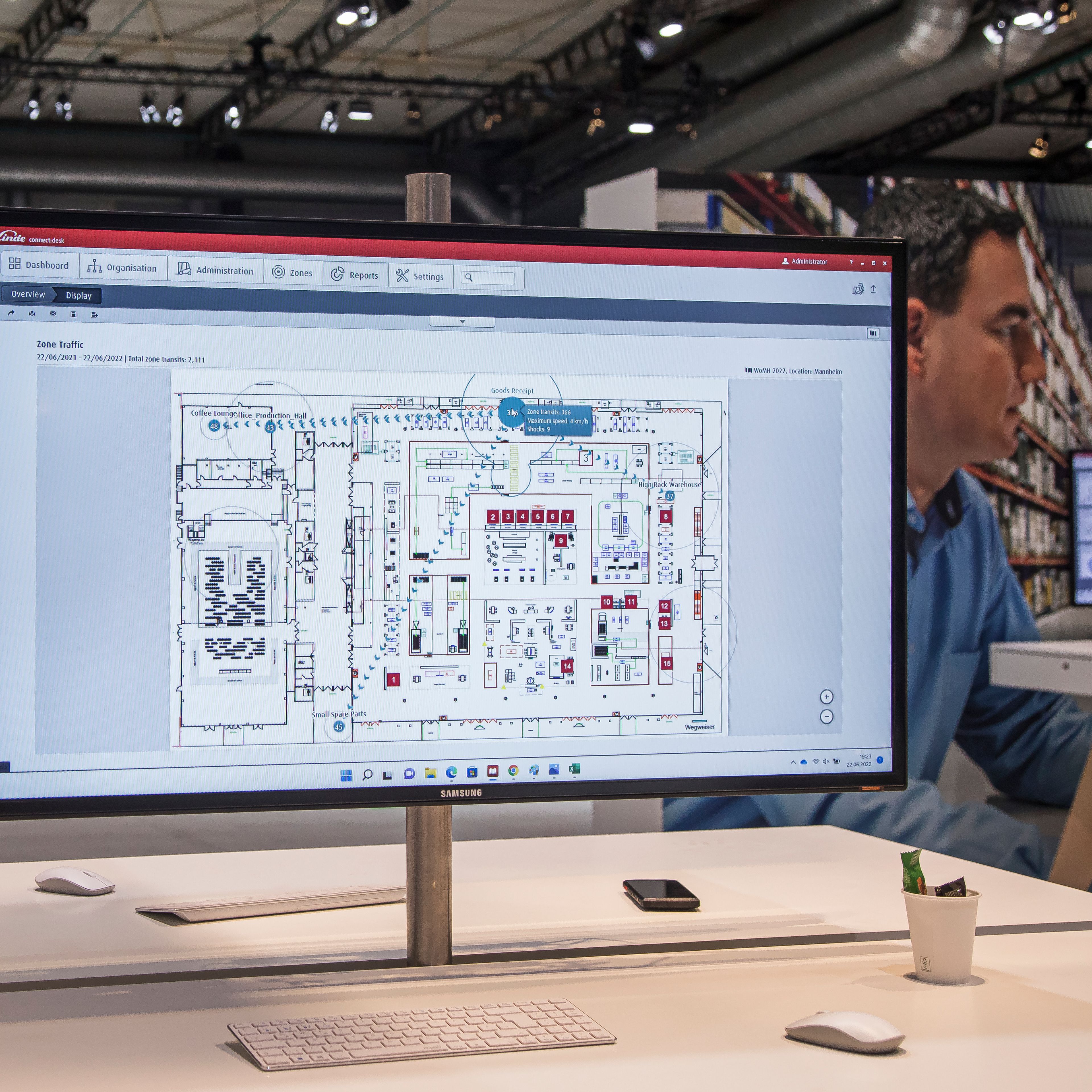

Warehouse Management System

Why have a WMS?

A warehouse management system (WMS) can be used by you as a customer to control and carry out every single movement of materials in the warehouse individually, including goods receipt, warehouse management and order picking, as well as trip planning and dispatch. In these processes, all relevant information is taken into account, such as information about load carriers and articles, such as batch number, best-before date, serial number and the respective storage strategies, to ensure that materials are delivered punctually and according to needs, while the storage space is utilized optimally. In addition, the system allows administration of empty goods and annual or permanent stock count.

Your advantages:

- Transfer of orders from the overall ERP system and comparison of data from the order (e.g. article, quantity, packaging) upon delivery.

- Handling of deliveries, sub-deliveries or partial deliveries, as well as quality control (e.g. sampling, visual inspection, 100% inspection).

- Goods are usually identified by mobile scanning of a barcode (EAN, NVE) on a terminal or with a handheld scanner.

- Automatic printing of labels and documentation, connection to scales.

- Photo documentation to register received goods.

LINDE

Linde Warehouse Manager

STILL